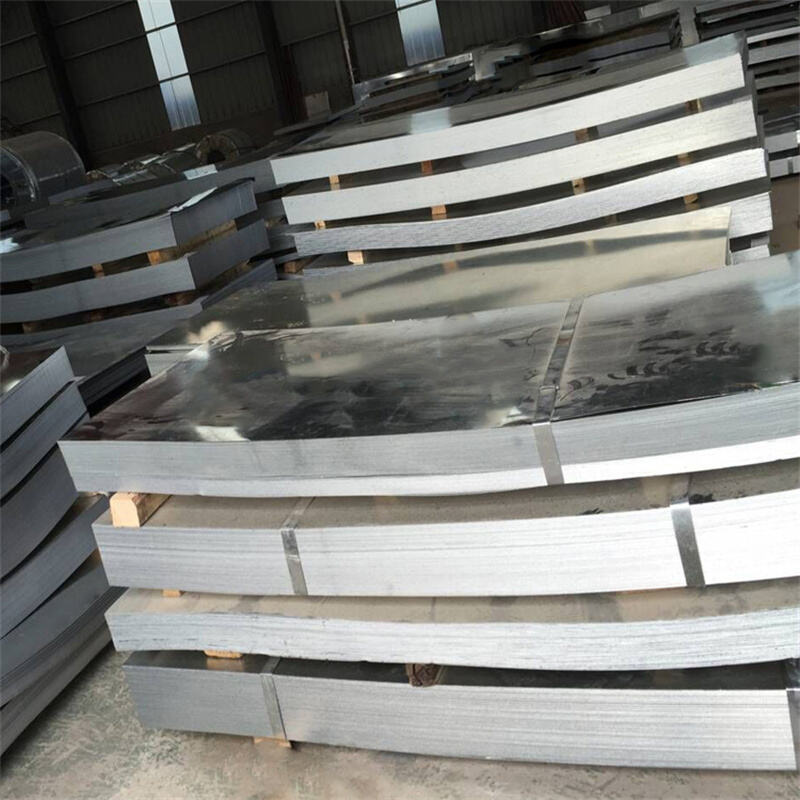

A remarkable metal that has a distinct characteristic which separates it from the rest and that is stainless steel, devoid of this particular quality known as chromium. It is a shield against rust and stains, which are why it catches the attention of architects, engineers as well as designers. The stainless sheet metal material from Taigang Puxin that never corrodes and keeps shining new is a perfect fit for our modern kitchen countertops, to city skylines of towering skyscrapers. When chromium forms a barrier to protect stainless steel from the elements, it reacts with oxygen in air this ensures that stainless does not rust further. This self-healing corrosion resistance, coupled with a high strength-to-weight ratio and inherent formability aid in its longevity; particularly in harsh environmental environments. For this reason, it is a material of choice for many outdoor and also industrial applications as they are extremely robust and practical materials to work with.

Stainless steel care and maintenance guidelines

To get your stainless steel to continue looking brand new like this one, you have work cut out for yourself. Because it is so highly polished, stainless steel shows fingerprints and nothing ruins a look of pristine quality faster than dirty smudges. The polished stainless sheet meta is one of my favorite finishes because it goes with everything- but oily fingers can smudge this finish and dirty up the look. If not wiped cleaned greasy fingerprints could result in tea-staining and slowly corrode the surface of the stainless steel. To maintain the appearance of stainless steel fittings, clean with warm soapy water and a soft cloth to prevent damage by use of abrasive cleaners. In corrosive settings, proactive steps such as frequent cleaning and treating of anti-corrosion coverings could possibly help protect stainless steel to retain its own appearance and perform correctly over time.

Welding and Form Tooling Tips from an Expert Stainless Steel

For example, welding stainless steel requires skill and precision. Attaining good corrosion resistance in a welded region necessitates properly matching the base metal chemistry with that of the filler wire. If improper welding occurs a pre-heat and post-weld descaling process can reduce the presence of impurities, ejecting undesirables while promoting reformation or restoration of that protective layer. Stainless steel work-hardens in a different manner to carbon steels, notably yielding sharp edges from the formation and bending processes created because of increased tensile stresses. The durability of stainless steel sheet metal can be further improved by annealing it after deformation, which keeps the material structurally and functionally intact for longer periods.

Stainless Steel: Recyclable and Green

Stainless steel; moreover, provides properties such as high-recyclability, making it environmentally benign for those of you looking to make the world a better place. Its potential for being repeatedly recycled, without loss of its original properties is what highlights it as a material that limits waste and promotes circular practices (CE). In fact, stainless steel can be considered as a clear example of contributing to carbon reduction in the manufacturing processes with more than 60% post-consumer use stainless originates spanning across ethical (green) principles? Choosing stainless steel, you can help create a sustainable and environmentally friendly world. Protection of the environment - since taking care of our planet is no longer weird, metal will be preferred by all those who think about the future decision in terms of sustainability and conscious consumption.

Consolidating the Nature Stainless Steel Finish

Stainless steel is also available in a variety of finishes, making it very adaptable to any aesthetic and functional need. Available from scratch-resistant #4 finishes to the bright grades 3 and 8, finishing can be made project specific optimizing aesthetics as well as durability. For high-traffic areas where scratches may result, brushed finishes work best and are easier to maintain over time whereas mirror finishes provide light reflection with a visually appealing look that accommodate numerous decor styles. Choose the finish according to what you aim for and your environmental situations because aesthetics combine with performance, it should be functional as well visually appealing. Art meets function in stainless steel, available for performance and sustainability - but also designed to serve up inspiration across a variety of applications.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS