Transforming the Steel Industry: Sustainability on the Rise.

The steel industry responsible for the backbone of global infrastructure and progress is on the verge of large-scale change. As the importance of sustainability in any sector becomes ever more pressing, it is the top steel manufacturing technology companies that have been paving the way with futuristic eco-friendly solutions that are shaping the industry with starry-eyed opportunities. The article was composed with the use of industry leaders’ insights, the inclusion of eco-friendly technologies they developed, the look at the top companies like Taigang Puxin that are redefining steel manufacturing, the technological steps other producers are taking, and the view of the future influenced by impactful tech firms.

introduction

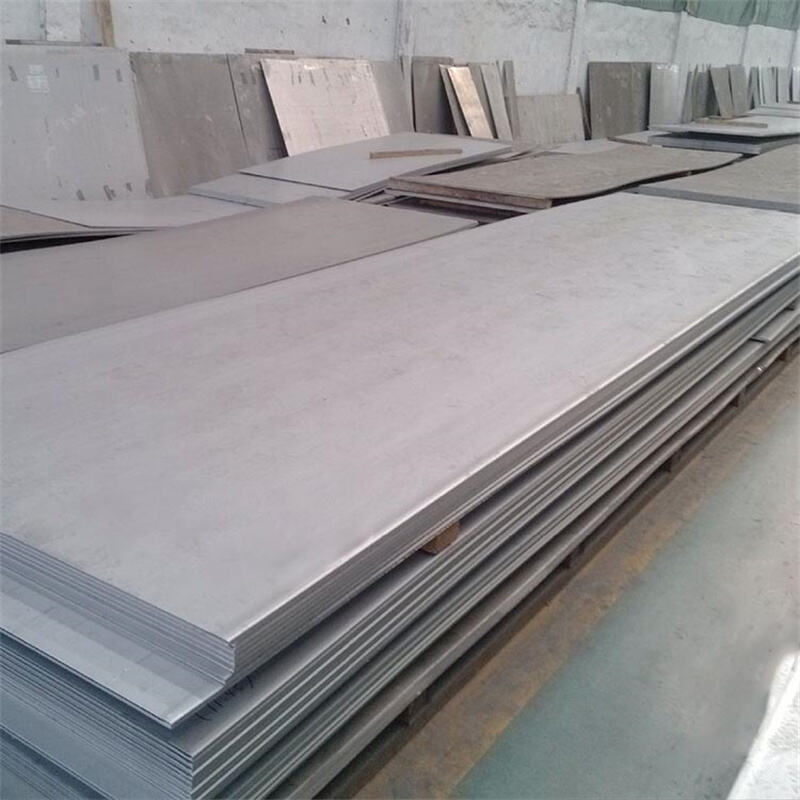

The giant steel manufacturers are not just accepting the latest tech as it comes; they change essentially what their business stands for. Those organizations are taking a page from the tech companies by investing heavily in research and development, developing an innovation culture borne out of years of challenging mainstream thinking. Utilizing Industry 4.0 principles, like IoT and smart factories for real-time monitoring with predictive maintenance improvements in process control. Not only does this improve efficiency, but it also enables tailored and adaptable manufacturing of Stainless steel sheet that can quickly respond to a wide variety of market needs in an environmentally sustainable way.

Unlocking the Tech Improvements of Leading Steel Makers

Major key steel producers are announcing new technologies that will take things a bit further than expected. Materials science has advanced to the point where state-of-the-art high-strength, lightweight steels like thin stainless sheet are able to save on material usage while ensuring that all structural requirements are met. The resource savings, in turn, mean not only better overall performance of the final product but also boost steel competitiveness over alternative materials. Additionally, the use of 3D printing in steel production allows for highly complex geometries that were once unattainable through traditional means to be created which provides designers with greater design flexibility and personalization.

The New World of Steel Making on The Tech Titans Side

The future of steel manufacturing is going to be defined by tech giants joining hands with traditional steelmakers. Its combined efforts are focused on the application of AI, Block Chain and advance robotics to improve traceability, transparency and efficiency across supply chain. For instance, the ethical sourcing of raw materials can be confirmed using blockchain and consumers would have access to a detailed view about how environmentally friendly their product was. Further, given the scale and falling cost of renewable energy production - plus just how techie these companies are relatively to incumbent steel firms - we could see a full transition to zero carbon steel like thin stainless steel sheets making wherever it is warranted by prudent deploy red technology.

The steel industry is meticulously being transformed by global giants and clever tech companies. The Modern Electric Vehicles have been paving the future of a post-carbon economy by relentlessly developing this technology and working with utilities, transport ministries and industries alike to continuously bring greener alternatives into existence. The steel industry itself will be a sign of human adaptability and innovation as the global challenges are resolved.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS