ġenerali

richiesta

Prodotti Relatati

Il-ċieċċ talbisa huwa aloys korrużjoni-resistenta ta' iż-żejg u kromju u, f’albaqijiet xiwa, nikkel u oħrajn metri.

Kompjetattivament u infinatament riċiklabli, il-ċieċċ talbisa jkun il-‘materja talba’ par eċċellenza. Infatti, wid-dawl konstruzzjonali, ir-recovery rate attwali tiegħu hija qrib għall-100%. Il-ċieċċ talbisa jkun ukoll ambientalment neutrali u inert, u l-ebda tagħmiem tiegħu jikkonvinċja li tinqablu l-għandhom tal-bniġi sostenibbli. Żgur jekk ma jissfuġx kompożizzjonijiet li jistgħu jagħmlu modifiki meta jkunu inkontatt ma elementi bħala l-ilma.

Ġewwa li dawn ir-reġali jambjentali, is-slejjum huwa wkoll estetikament appella, ħajjinissim, sibħ li jkollok, duri tal-ġdid u jagħmel disponibbli varjetà kbar ta' aspetti. Kif reżultat, is-slejjum jistgħu jinkura f’ċerċa ta’ oggetti kuljumi. Jghallix jekkum ruoli prominen fiċ-ċikkara ta’ industrijiet, inklużivment l-enerġija, it-transport, it-tieqa, ir-riċerka, il-mediċina, is-swieq u l-loġiġi.

Fornitur Professjonal tal-Metal - ZLYS minn Ċina

15 snin ta' esperjenza fil-ħaddijiet tal-accja, Għandna jkunu team professionali biex jagħmlu skontroll tas-sigena tal-prodotti ta' slejjum u prodotti oħra metalettiku kollha mill-manufattura sino’ l-fornitura, dan jippermetti li nassiguraw in-nifs siegħa minn semplifikazzjoni tal-materiali raw b’seħa għall-proċessarli dwar li jinkludi prodotti finizzati, marjiem, pakkaġġ, konservazzjoni u transport.

Niġru wieħed mill-pjoġġ tal-kbir fornituri ta' slejjum minn Ċina.

ZLYS steel hija l-oħlo post għall-iskopja tal-aċjar tas-sider jew karboni/tass-aluminium. Jekk inti tibgħad servizzijiet ta' qualità b'varjetà kbira ta' prodotti, allura bizness tiegħi huwa aħjar għalik.

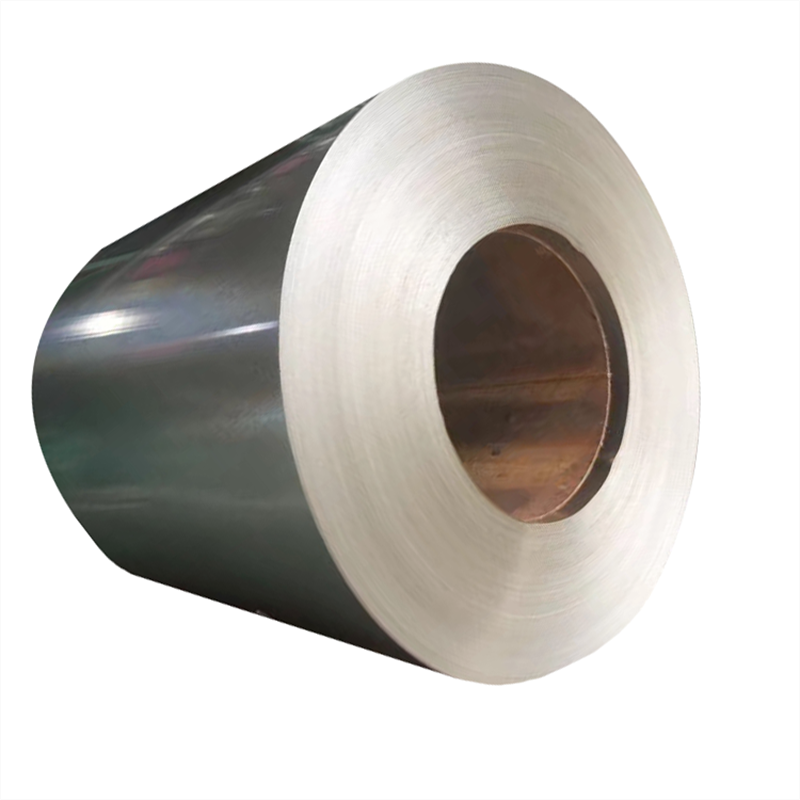

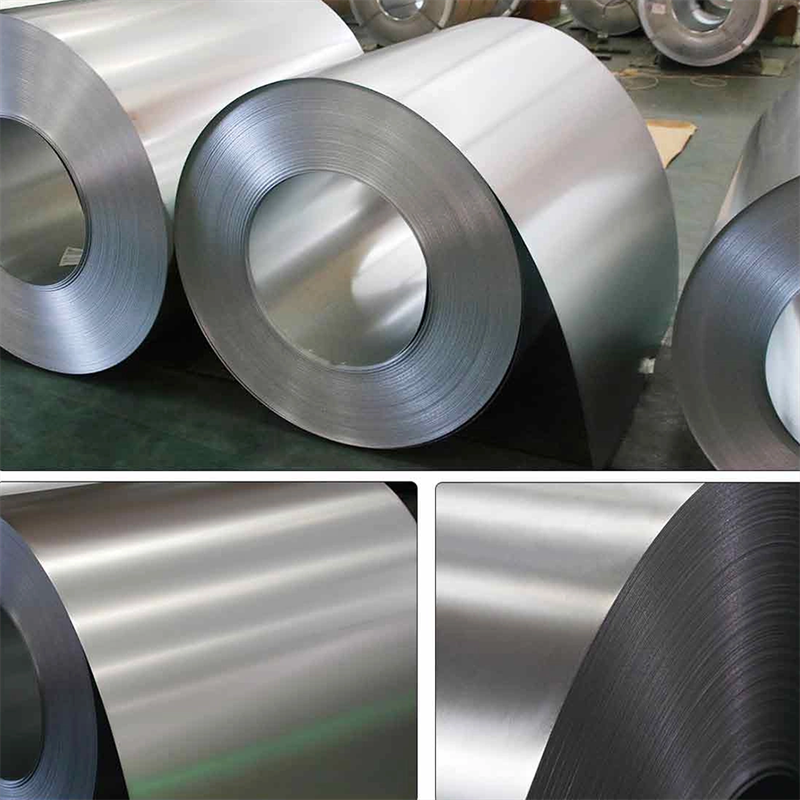

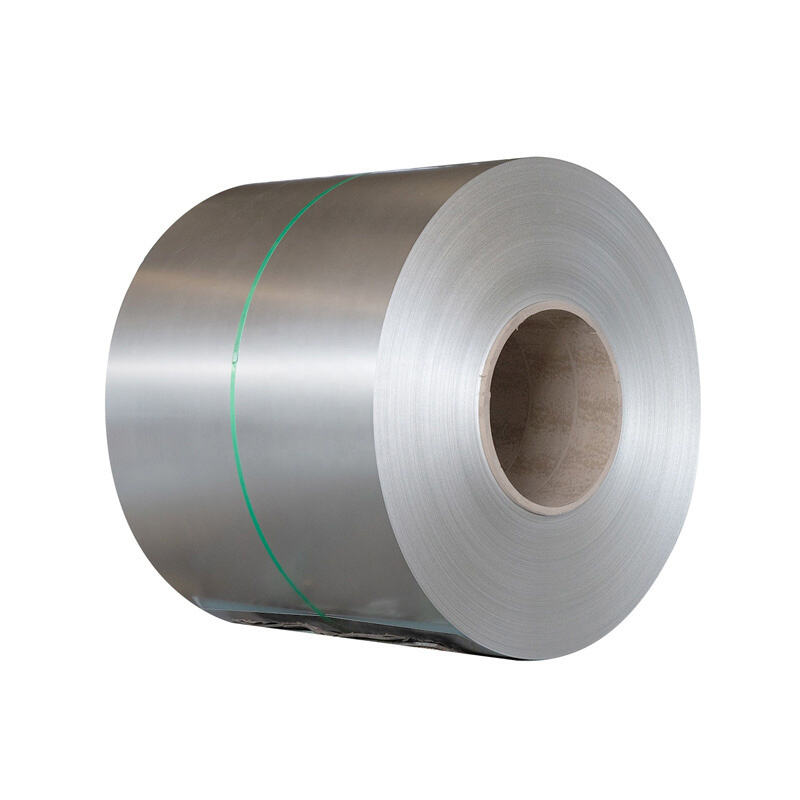

Aqbiżja għall-koleji tiegħek tal-sider

| Skont il-reqwest tiegħek, kull dimensjoni tista' tkun muntizza għall-applikazzjoni differenti. Skontati! | |

| Isem tal-Prodott | Levija/Plata Sider Tass-Sidr |

| It-tul | Skont ir-riċhiema |

| Il-wisa' | 3mm-2000mm jew kif timgħod |

| Thickness | 0.1mm-300mm jew kif timgħod |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, wkj. |

| Tecnika | Ġdid rollat \ friġ rollat |

| Trattament superficjali | NO.1, 2B, NO.4, BA, HL jew Skont ir-reqwiżitu tal-klijent |

| Tolleranza tal-ġewwa | ±0.01mm |

| Materjal | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321, 310S 309S, 410, 410S, 420, 430, 431, 440A, 904L, eccetera |

| APLIKAZZJONI | Jkollha użu kbir fis-sitwazzjonijiet ta' temperatura alta, appjari mediku, materjali ta' biġiema, kemjia, industria tal-ilma, agrikoltura, komponenti tal-baħar. Japplika ukoll għall-ilma, pakkiġġ tal-bibbli, supplji tal-kukina, trenni, aeroplan, konvejuri, vetturi, bolti, skruwi, molle, u schermi. |

| MOQ | 1 tonna, Nixtieq nikkablu ordini ta' sampli. |

| Ħin ispeċifikattiva | F’ħaddi 7-15 jum ta’ travaglio bażjani rċiep il-depożitu jew L/C |

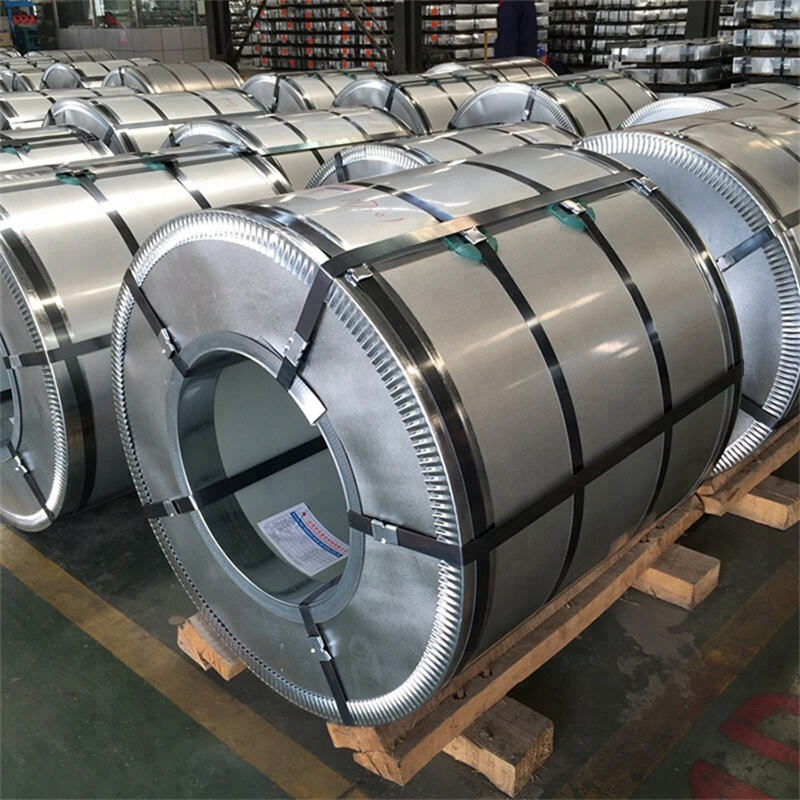

| Pakkatġġa għall-esportazzjoni | Ħaddiel papier, u sider imballat. Pakk standard għall-esportazzjoni marittima. Aħjar għall-transport tat-tipijiet kollha, jew skont ir-reqwiżiti. |

| Kapacità | 25000 tonni/ċied |

Fornitura tal-Materiali

| Fornitura tal-Materiali: | ||||||||||||

| Gradi ASTM/ASME | Grada EN | Kompjoni Kimika % | ||||||||||

| C | Cr | Ni | Mn | P | S | mo | Iev | Cu | N | Żgħar | ||

| 201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - | |

| 301 | 1.431 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | 0.1 | - |

| 304 | 1.4301 | ≤0.08 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | - |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | - |

| 304H | 1.4948 | 0.04~0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | - |

| 309s | 1.4828 | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | - |

| 309H | 0.04~0.10 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | - | |

| 310S | 1.4842 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.5 | - | - | - |

| 310H | 1.4821 | 0.04~0.10 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.5 | - | - | - |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤0.75 | - | - | - |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤0.75 | - | - | - |

| 316H | 0.04~0.10 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤0.75 | - | 0.10-0.22 | - | |

| 316TI | 1.4571 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤0.75 | - | - | Ti5(C+N)~0.7 |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤0.75 | - | 0.1 | - |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | 0.1 | Ti5(C+N)~0.7 |

| 321H | 1.494 | 0.04~0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | 0.1 | Ti4(C+N)~0.7 |

| 347 | 1.455 | ≤0.08 | 17.00-19.00 | 9.00-13.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | Nb≥10*C%-1.0 |

| 347H | 1.4942 | 0.04~0.10 | 17.00-19.00 | 9.00-13.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤0.75 | - | - | Nb≥8*C%-1.0 |

| 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | 0.03 | Ti6(C+N)-0.5 Nb0.17 |

| 430 | S43000 | ≤0.12 | 16.00-18.00 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 436 | S43600 | ≤0.025 | 16.00-19.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 0.75-1.0 | ≤1.00 | ≤0.025 | Nb+Ti:8(C+N)~0.80 | |

| 439 | S43035 | ≤0.030 | 17.50-18.50 | - | ≤1.00 | ≤0.040 | ≤0.015 | - | ≤1.00 | - | ≤0.030 | Ti+Nb:0.2+4C~0.75 |

| 441 | S44100 | ≤0.030 | 17.50-18.50 | - | ≤1.00 | ≤0.040 | ≤0.015 | - | ≤1.00 | - | ≤0.030 | Ti:0.1-0.6 Nb:3C+0.3~1.0 |

| 442 | S44200 | ≤0.025 | 18.0-23.0 | - | ≤1.00 | ≤0.040 | ≤0.035 | - | ≤1.00 | - | ||

| 443 | S44300 | ≤0.025 | 19.5-22.0 | - | ≤1.00 | ≤0.035 | ≤0.015 | - | ≤1.00 | - | ≤0.025 | Nb+Ti:0.2+4(C+N)~0.75 |

| 444 | S44400 | ≤0.025 | 17.00-20.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | ≤0.035 | Ti+Nb:0.2+4(C+N)~0.8 | |

| 446 | S44600 | ≤0.2 | 23.0-27.0 | 0.75 | ≤1.50 | ≤0.040 | ≤0.030 | - | ≤1.00 | 0.25 | ||

| 410 | 1Cr13 | 0.08~0.15 | 11.50-13.50 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410J1 | 1Cr13Mo | 0.08-0.18 | 11.50-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 0.30-0.60 | ≤1.00 | - | - | - |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 431 | 1Cr17Ni2 | ≤0.2 | 15.00-17.00 | 1.25-2.50 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 440c | 11Cr17 | 0.95-1.20 | 16.00-18.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 0.75 | ≤1.00 | - | - | - |

| 17-4PH | 630\/1.4542 | ≤0.07 | 15.50-17.50 | 3.00-5.00 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb+Ta:0.15-0.45 |

| 17-7PH | 631 | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | |||

| Il-post tal-oriġini | Wuxi, Ċina |

| Materjal | Aċjar karbon, Aċjar jisus, Galvanizzat |

| Termini ta' Ħlas | T/T, L/C, Western Union, itt. |

| Stil tad-Disinn | Posżibbli li jkun modifika |

| Ħin ta' Kunsinna | 7 ijiem |

| Transport | Bħala trasport tal-baħar jew tas-saqafa |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS