Overview

Inquiry

Related Products

Stainless Steel Bar Alloys

Our inventory of stainless steel bar products includes 303 stainless steel bar, 304 stainless steel bar, and 316 stainless steel bar. For more grade and detailed information, feel free to contact with us.

Stainless steel can be used for environments or applications that require chlorine or alkaline exposure

Stainless steel can withstand highly acidic environments

Round bar is used for a wide range of industrial uses, including structural applications as well as industrial shafts.Stainless steel according to the use of processing method is divided into: pressure processing steel and cutting steel; According to the characteristics of tissue, it can be divided into five types: austenite type, austenite - ferrite type, ferrite type, Martensite type and precipitation-hardening type.

303 Stainless Steel Round Bar

Ideal for automated machining applications, 303 stainless steel round bar is available with an annealed cold finish. Known for its machinability, the inclusion of sulfur lowers the corrosion resistance when compared to other stainless steel grades.

Used for machining applications304 Stainless Steel Round Bar

As a versatile stainless steel alloy, 304 stainless steel round bar is used widely for commercial and industrial applications. Easily weldable and fabricated, it also offers good corrosion resistance. 304 SS is a heat-resistant alloy with good formability.Ideal for heavy gauge parts or components

316 Stainless Steel Round Bar

With a higher molybdenum content than alloy 304, 316 stainless steel round bar is well suited for highly corrosive environments such as marine or outdoor applications. Easily formable and weldable, 316 stainless steel round bar is suitable for chemical processing and food prep equipment.

Suitable for medical instruments due to its hygienic and non-reactive properties

Applications for SS Round Bar

Stainless steel round bar can also be used for the following applications:

Railings

Beams

Handles

Braces

Shafts

Fasteners

While your application requirements will determine which metal is best suited for your needs, stainless steel round bar is often a great substitute for carbon steel. It offers better corrosion resistance and surface finishes.

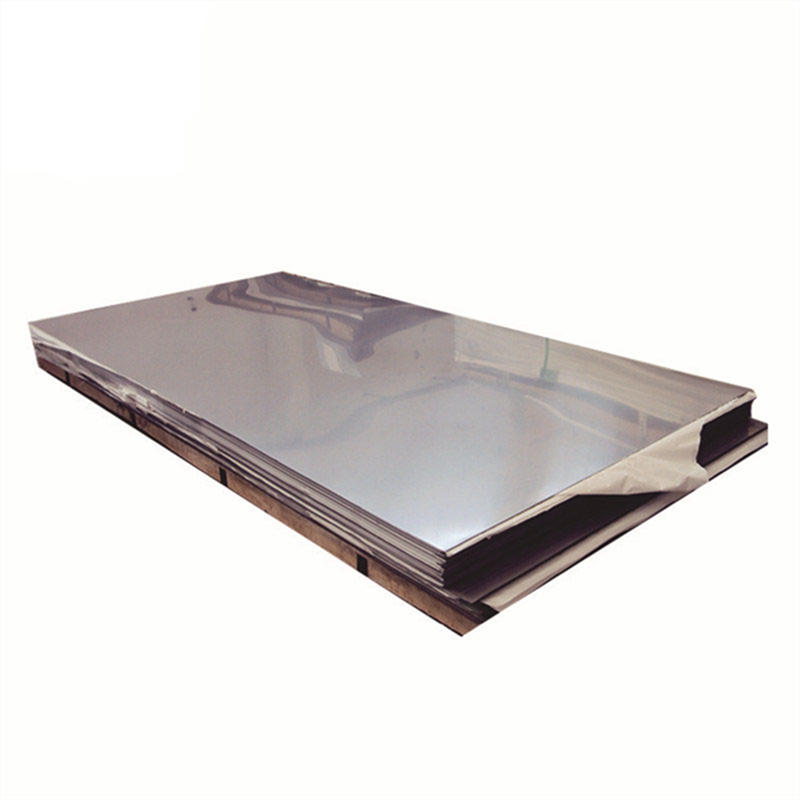

Finishing Options

Common stainless steel finishing options include:

Mill Finish (2B)

Brushed

Mirror

Bright Annealed

Buy Stainless Steel Bar from a Professinal Metal Supplier

Find the right round stainless steel bar product for your needs.

| Specifications of Stainless Steel Bar | |||

| Commodity | Stainless Steel Round Bar/Flat Bar/Angle Bar/Square Bar/Channel | ||

| Standard | AISI, ASTM, DIN, GB, JIS, SUS | ||

| Material | 301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202,321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100,S30400, S30403, S30908, S31008, S31600, S31635, etc. | ||

| Certification | SGS, BV, etc | ||

| Surface | Bright, Polished, Turn smooth(Peeled),Brush, Mill, Pickled etc. | ||

| Delivery Time | 7-15 days after confirming the order. | ||

| Trade Time | FOB, CIF, CFR | ||

| Payment | T/T or L/C | ||

| MOQ | 1 Ton | ||

| Specification | Item | Size | Finish |

| Stainless steel round bar | 19*3mm-140*12mm | Black&Pickled&Bright | |

| Stainless steel flat bar | 19*3mm-200*20mm | Black&Pickled&Bright | |

| Stainless steel square bar | Hot rolled: S10-S40mmCold rolled: S5-S60mm | Hot rolled&Annealed&Pickled | |

| Stainless steel angle bar | 20*20*3/4mm-180*180*12/14/16/18mm | White acid& Hot rolled&Polished | |

| Stainless steel channel | 6#, 8#, 10#, 12#, 14#, 16#, 18#, 20#, 22#, 24# | White acid& Hot rolled&Polished&Sandblast | |

| Chemical Properties ofStainless Steel Material Grade | |||||||||||

| ASTM | UNS | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| 201 | S20100 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0.06 | ≤0.03 | ≤1.00 | 16.00-18.00 | 3.5-5.5 | - |

| 202 | S20200 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0.06 | ≤0.03 | ≤1.00 | 17.00-19.00 | 4.0-6.0 | - |

| 301 | S30100 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.00-18.00 | 6.0-8.0 | - |

| 304 | S30400 | 1.4301 | SUS304 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.00-20.00 | 8.0-10.5 | - |

| 304L | S30403 | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.00-20.00 | 8.0-12.0 | - |

| 309S | S30908 | 1.4883 | SUS309S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 22.00-24.00 | 12.0-15.0 | - |

| 310S | S31008 | 1.4845 | SUS310S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.50 | 24.00-26.00 | 19.0-22.0 | - |

| 316 | S31600 | 1.4401 | SUS316 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.00-18.00 | 10.0-14.0 | - |

| 316L | S31603 | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.00-18.00 | 10.0-14.0 | 2.0-3.0 |

| 317L | S31703 | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.00-20.00 | 11.0-15.0 | 2.0-3.0 |

| 321 | S32100 | 1.4541 | SUS321 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.00-19.00 | 9.0-12.0 | 3.0-4.0 |

| 347 | S34700 | 1.455 | SUS347 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.00-19.00 | 9.0-13.0 | - |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS