Coil Galvanized - Protecting and Enhancing Materials

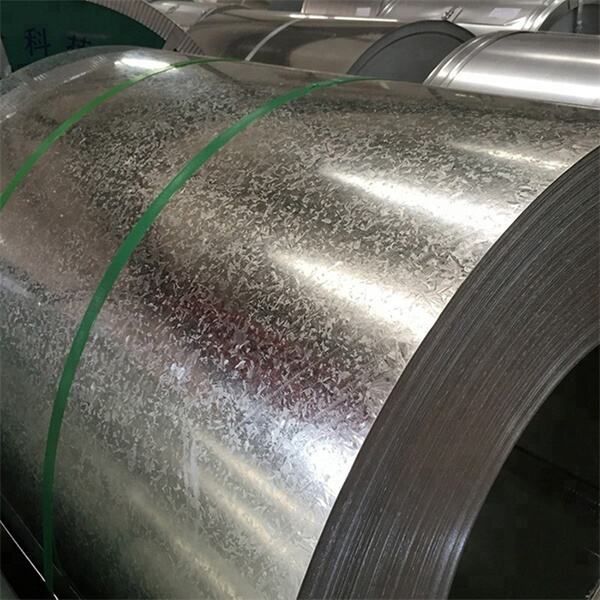

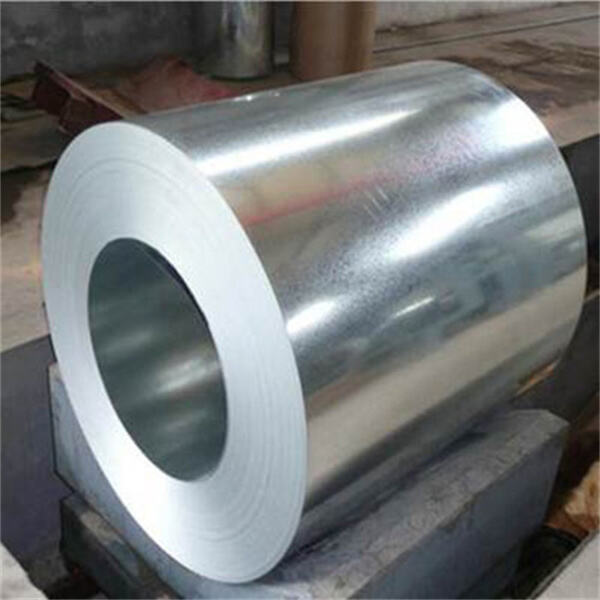

Coil galvanized is an ongoing process that helps in protecting materials from corrosion and wear. It really is a popular technique offers materials an extended lifespan increases its durability. In simple words, Taigang Puxin coil galvanized is merely a process of coating metal surfaces with a layer of zinc by dipping it in a bath of hot molten zinc. This technique is widely used in various applications because of its numerous advantages innovation, and safety features.

Coil galvanized offers several advantages which allow it to be a coating popular technique. Firstly, it is a cost-effective process that provides excellent protection to your underlying metal. Next, the zinc layer acts as a natural barrier corrosion rust, protecting the metal linked to the harmful effects of moisture, salt, along with other corrosive elements. Thirdly, Taigang Puxin steel coil galvanized really is a durable layer can last for the long duration, making the materials stronger and increasing their lifespan.

Within the full years, coil galvanized has evolved, and new innovations been introduced to improve the method further. There are many techniques of Taigang Puxin galvanized steel coil now, including hot-dip galvanizing, electro galvanizing, and mechanical galvanizing. These new techniques improved the durability and quality of this coating, which makes it ideal for various applications.

Coil galvanized is a secure and reliable procedure has minimal risks of harm or injury if performed correctly. The process of Taigang Puxin galvanized coil involves dipping the materials in hot molten zinc, and hence safety precautions need to be taken. Workers contained in handling the gear should wear protective gear gloves, goggles, and aprons to stop any accidental burns or accidents. However, with proper training and safety gear, the method of coil galvanizing can be executed safely.

Coil galvanized can be utilized on various materials, including metal, aluminum, and iron. The method involves cleaning the surface associated with steel to remove any dirt or paint after which dipping it into a bath of molten zinc. The Taigang Puxin galvanised steel coil typically uses a vat of molten zinc heated to around 840°F to 850°F. The process of electro galvanizing is just a little different as the application is involved by it of zinc with an electric current. Mechanical galvanizing uses powder to layer the materials. However, each process requires skills equipment specific.

are a part steel shows coil galvanizedyear, the majority of our customers enjoy been with for long time.

hold a huge amount of stock coil galvanizedsizes in order to guarantee quick delivery time. Typically, the steels can shipped within 3 business days following date of payment. Packaging can also tailored the needs of buyer.

main items include stainless steel,galvanized carbon steel. Including coils, coil galvanized, bars, pipes other steel profiles. The majority of them customized with low mininum quantity.

expert inspection coil galvanizedable to ensure the highest quality each shipment. We also certified through ISO9001,CE.SGS. If client needs other tests, will discuss the matter with them.