Overview

Inquiry

Related Products

Distributor of nickel alloys from China.

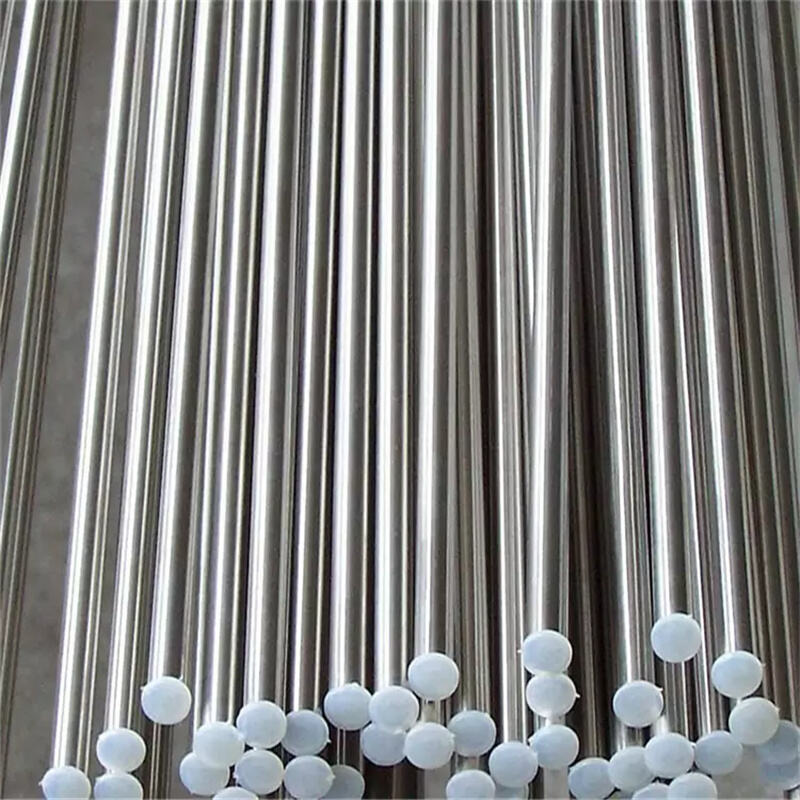

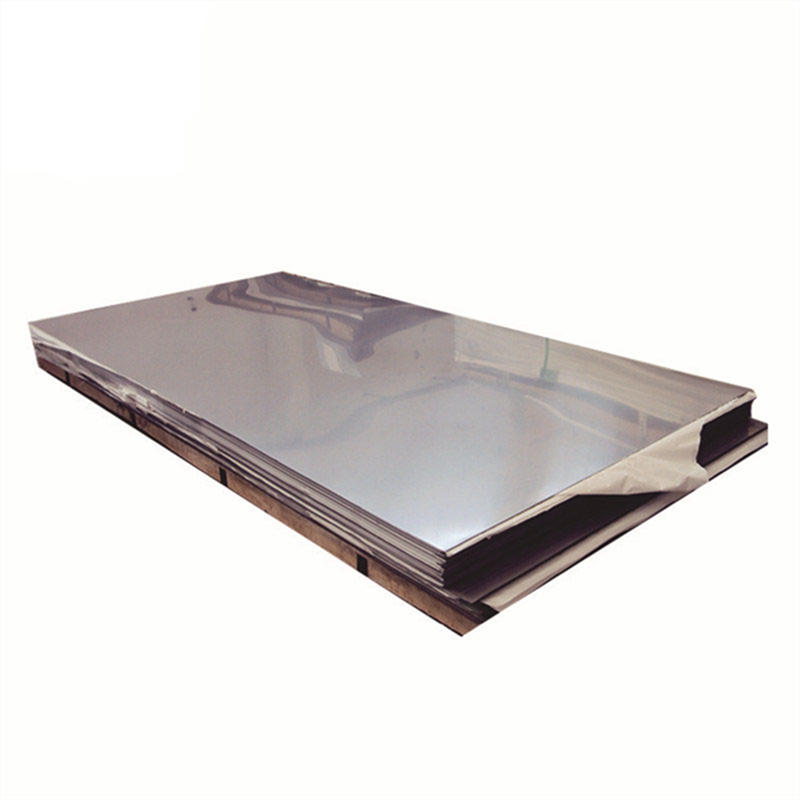

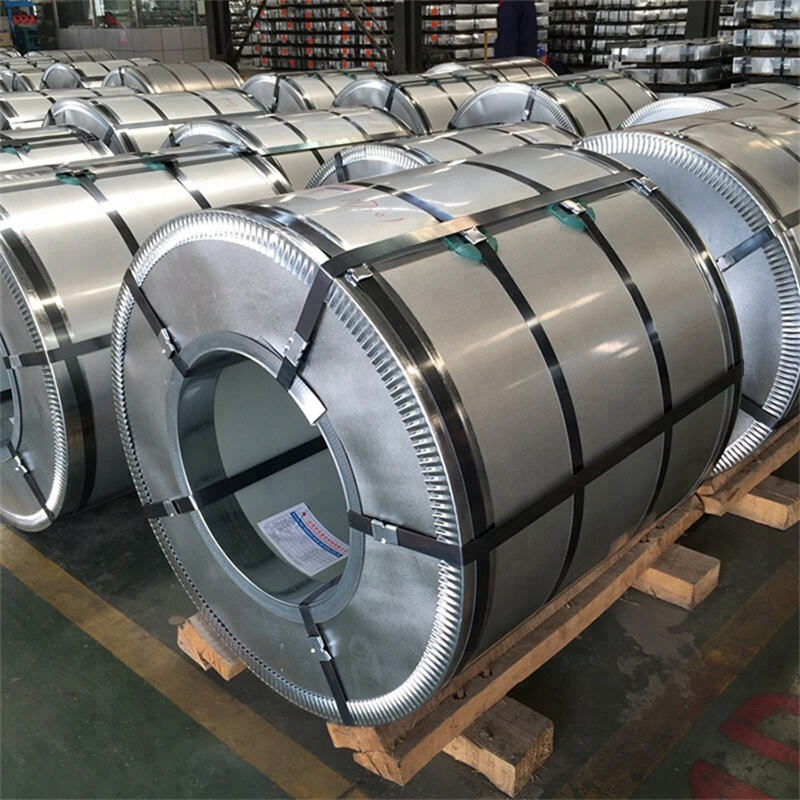

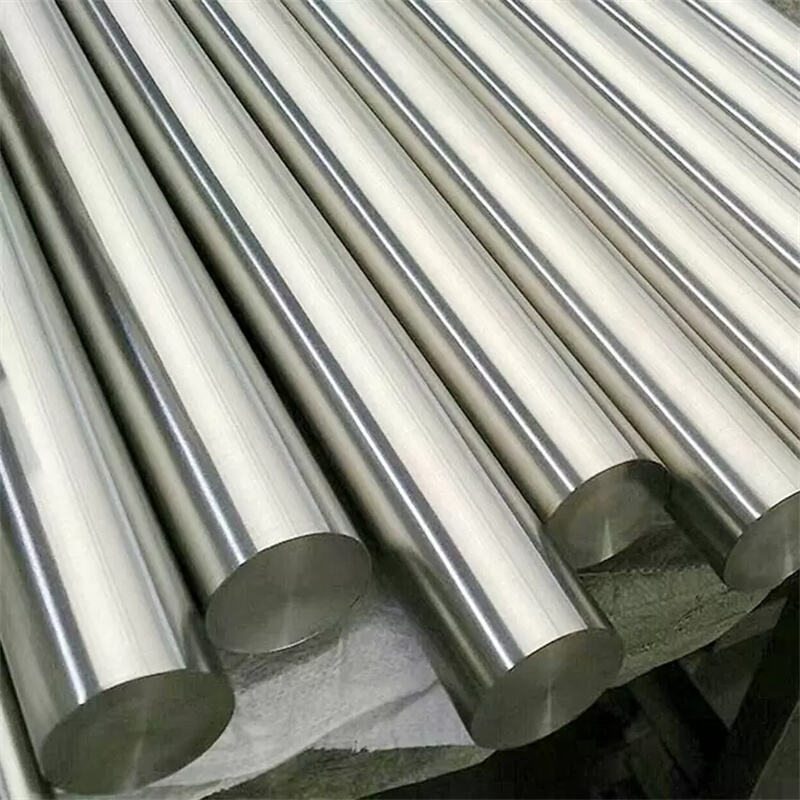

Forms available include pipes, bars, tubes, rods, sheets, plates, coils, angles, channels, beams, rolls, and strips. Products are available in different shapes and sizes.

Services include slitting, leveling and tension leveling, shearing and shearing, plate burning, annealing, turning and polishing, warehousing and repackaging, painting, chemical milling, grinding, plasma cutting, saw cutting, heat treating, honing, galvanizing, laser cutting, centerless grinding, exporting, shipping, export packaging, production shearing, and coil leveling.

Markets served to include chemical, automotive, aircraft, aerospace, medical, mechanical, and food.

Some common elements that nickel is alloyed with to form nickel alloys included iron, copper, chromium, manganese, carbon, and silicon. As a result of the wide range of elements that nickel is able to alloy too, there is a correspondingly vast number of industries that nickel alloys are utilized in including medical, power generation, nuclear power plants, and varied other applications; military, used in weapons, vehicles; industrial manufacturing, various machinery; marine, for shipping vessels and aerospace.

There are a vast number of nickel alloys, which are often categorized in terms of their second most prominent element, the characteristics they display, or the uses theyarebeing put to. For instance, nitinol is also called a nickel-titanium alloy or a shape memory alloy. Another example is nichrome, also called a nickel-chromium alloy or an electrical resistance alloy. Some other popular types of nickel alloys include Hastelloy, Cupronickel, Monel, Inconel, German silver, and Alumel.

UNS N06600, W.Nr. 2.4816

Inconel (nickel-chromium-iron) alloy 600 is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

The high nickel content gives the alloy resistance to corrosion by many organic and inorganic compounds and also makes it virtually immune to chloride-ion stress-corrosion cracking. Chromium confers resistance to sulfur compounds and also provides resistance to oxidizing conditions at high temperatures or in corrosive solutions.The alloy is not precipitation hardenable; it is hardened and strengthened only by cold work. The versatility of Inconel alloy 600 has led to its use in a variety of applications involving temperatures from cryogenic to above 2000°F (1095°C).

The alloy is used extensively in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

Inconel nickel-chromium-iron alloy 601 (UNS N06601/W.Nr. 2.4851)

is a general-purpose engineering material for applications that require resistance to heat and corrosion. An outstanding characteristic of Inconel alloy 601 is its resistance to hightemperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined and welded.

UNS N06625, W.Nr. 2.4856

Inconel 625 is a nickel-chromium alloy with an addition of molybdenum and niobium. These additions give the alloy better mechanical properties and better corrosion resistance without having to harden the material. Inconel 625 is used in offshore and aerospace industries, but also in pollution control equipment.

Inconel alloy 686 (UNS N06686/W.Nr. 2.4606)

is a single-phase, austenitic Ni-Cr-Mo-W alloy offering outstanding corrosion-resistance in a range of severe environments.

UNS N07718, W.Nr. 2.4668

Inconel 718 is a precipitation-hardenable nickel-chromium alloy also containing significant amounts of iron, niobium and molybdenum along with lesser amounts of aluminium and titanium. The alloy combines corrosion resistance and high strength with oustanding weldability including resistance to post-weld cracking. Inconel 718 has excellent creep rupture strength at temperatures to 700°C. We stock both solution annealed AMS 5662 and age hardened AMS 5663. The alloy is used in gas turbines, rocket motors, spacecraft, nuclear reactors and pumps.

Inconel alloy X-750 (UNS N07750/W. Nr. 2.4669)

is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. Alloy X-750 also has excellent properties down to cryogenic termperatures. The economics of Inconel alloy X-750 coupled with its availability in all standard mill forms has resulted in applications in a wide variety of industrial fields. In gas turbines, it is used for rotor blades and wheels, bolts, and other structural members. Inconel alloy X-750 is used extensively in rocket-engine thrust chambers. Airframe applications include thrust reversers and hot-air ducting systems. Large pressure vessels are formed from Inconel alloy X-750. Other applications are heat-treating fixtures, forming tools, extrusion dies, and test machine grips. For springs and fasteners, Inconel alloy X-750 is used from sub-zero to 1200°F.

Specializing in non-standard and custom-made Alloy Steel items, we have what you are looking for, including the competence to provide a vast range of materials from stock to suit your needs.

Our specialties include:

Highly specialized non-standard material

Off the shelf items

Prototypes through production

Low minimums to mill run.

ZLYS has the experience to solve your most difficult requirements.

Quote to discuss your needs or to talk to an experienced member of the sales team.

With our focus on superior customer service, premium quality, and expedited turnaround, you will agree that ZLYS is your best source for metal.

15 years of experience in the steel industry, We have a professional team to maintain the quality of Stainless Steel products and other metal products throughout the manufacturing and supply i.e from the process of selection of high-quality raw material to processing it into a finished product, marking, packaging, storage, and transportation.

ZLYS steel is the best place to buy stainless steel/nickel-based alloy products. If you are looking for quality services with a wide range of products, then our business is better for you.

| Material | Monel/Inconel/Hastelloy/DuplexSteel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31 | |

| Hastelloy:HastelloyB/-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g | |

| Hastelloy B/UNS N10001,Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617,Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610,Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602,Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819,Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188 | |

| Inconel600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851,Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

| Specification | Wire: 0.01-10mmStrip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mmPipe: φ6-273mm;δ1-30mm;Length 1000-8000mmSheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machinemanufacturingand combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS